What You Must Know About Piercing Thicker Plate with Plasma

The ability to pierce metal plate is a necessity for many fabricators and steel processing centers. This back-to-basics tutorial explains why using plasma, rather than oxyfuel, is most desirable as it means faster piercing times, faster cut speeds, and a cleaner finished product that translates into higher productivity and profitability.

Posted: February 11, 2013

Despite the many benefits of plasma technology, some companies have found piercing thicker material – say anything over 1¼ in – difficult with their older plasma systems. They aren’t alone. Several factors have often left operators with a torch filled with melted consumables, or consumables covered in a quick layer of dross.

Thanks to improvements in plasma torch and consumable design, the piercing capabilities of plasma are now so significantly better that it’s time to revisit the factors that have traditionally impacted piercing, as well as the technological advancements that are making plasma a worthy choice when it comes to piercing thicker material.

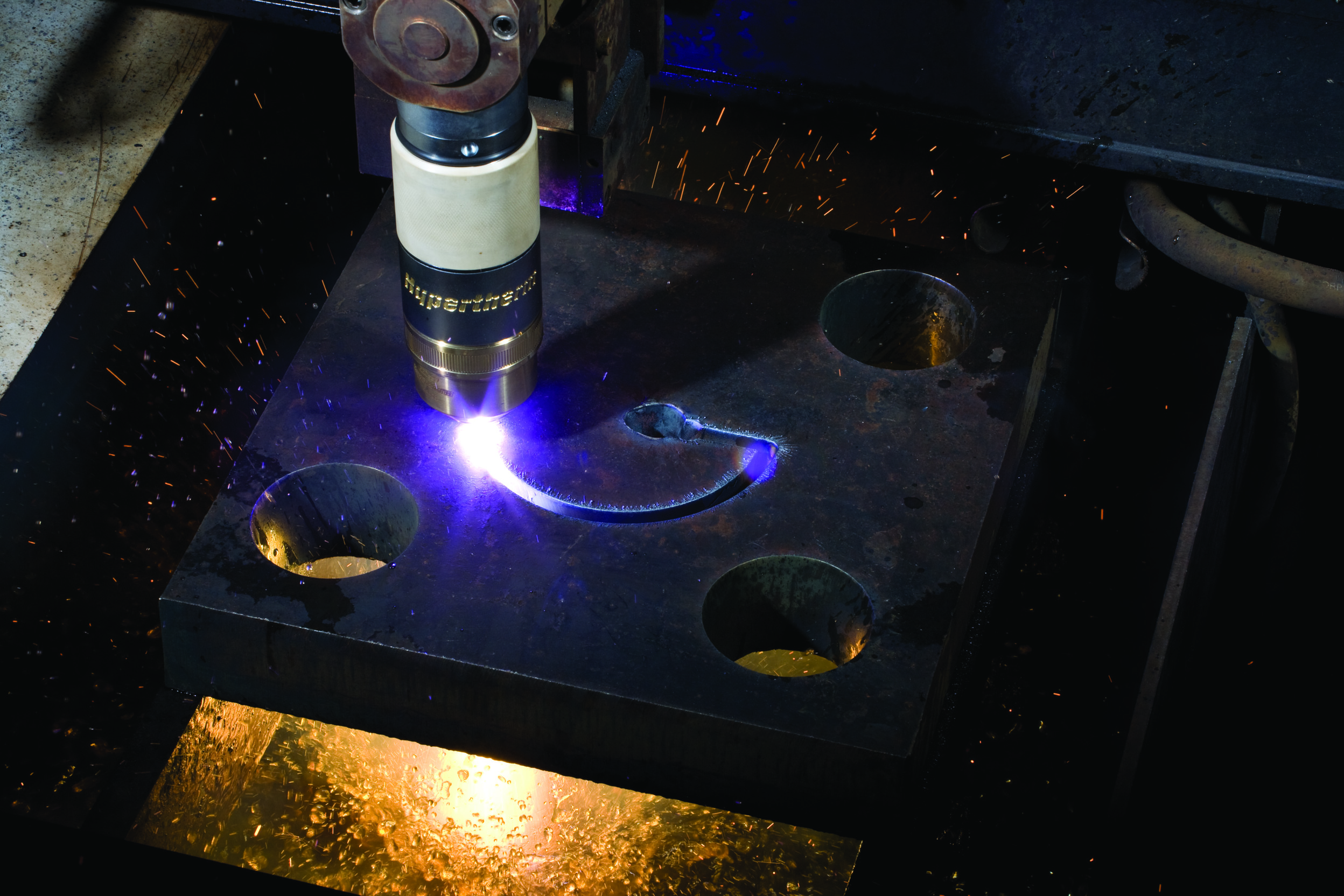

THE PIERCING PROCESS

Let’s begin by taking a look at the piercing process. When piercing with a plasma torch, the plasma arc attaches to the top surface of the plate and transfers enough energy to melt the metal near the top.

This molten material must then be removed, usually accomplished with the non-current carrying cold gas and the plasma shielding gas.

As this molten material is removed, the arc transfers the energy to the bottom of the pierce hole and melts deeper into the plate. This process continues as the arc penetrates deeper into the plate until it is through.

PIERCING TECHNIQUES

Operators of plasma systems employ various techniques, either alone or in combination with other methods, to address the limitations of piercing thick metals:

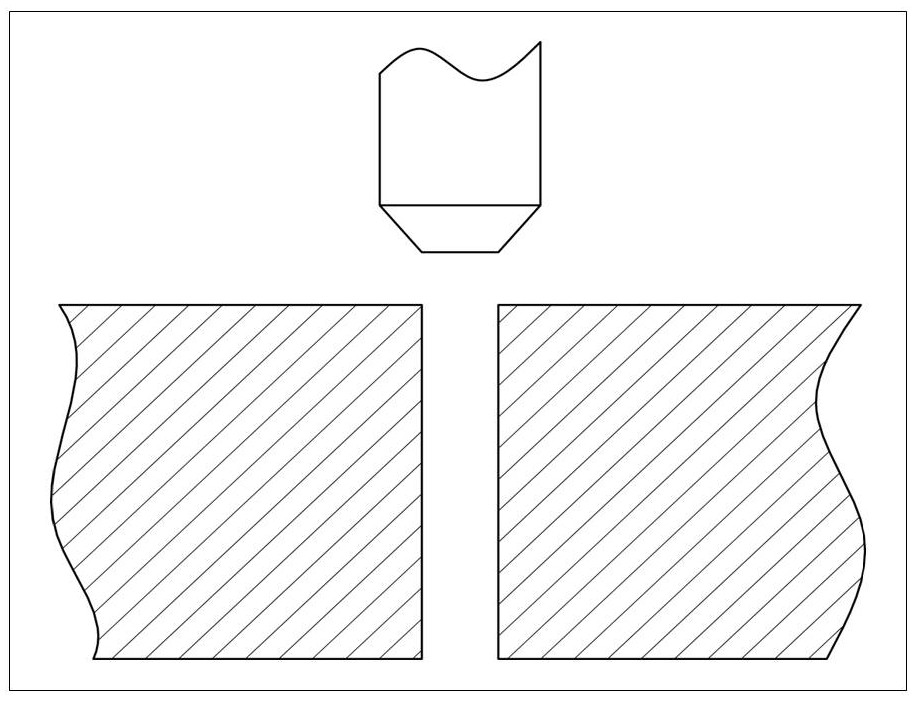

Stationary Pierce Method

In the stationary pierce process, the torch remains stationary during the entire piercing operation, generally at the manufacturers’ recommended pierce height (Figure 1).

After the plasma arc pierces through the plate, the torch drops to the cut height and begins the cut.

If there is a significant slag puddle on the surface of the plate, the torch can remain at an elevated height until the torch motion has moved beyond the pierce puddle.

This is the simplest and most straightforward piercing technique currently used in the industry. Limitations of this technique include damage to torch and consumables as well as increased operating costs.

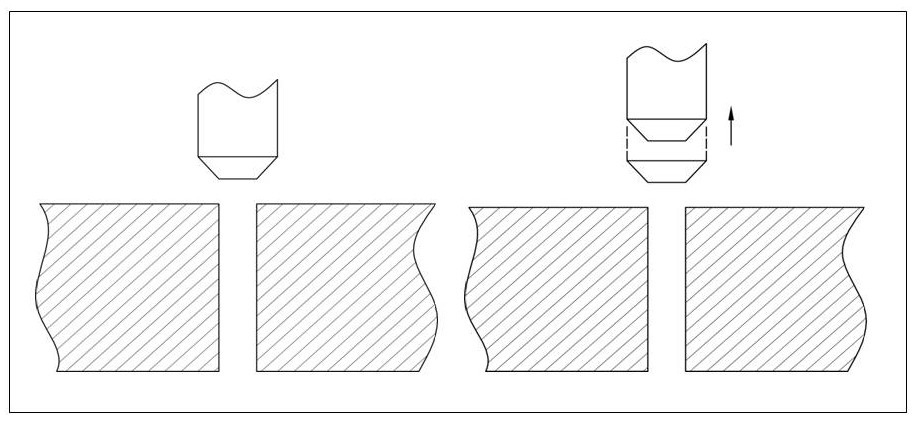

Low Transfer/Stretch Arc Method

In the low transfer/stretch arc method, the torch is raised once the plasma arc has transferred to the plate, stretching the arc (Figure 2).

By increasing the distance between the torch and the plate, the torch and shield are somewhat removed from the path of the material being ejected.

A major drawback of this method is that the elevated torch height, when combined with the depth of the hole, can drive voltages to a very high level, thereby increasing the probability that the arc will lose energy and even snap out.

While the impact to the torch and consumables is reduced using higher pierce heights, the resulting pierce times are generally longer and not all lifters and controllers can perform this technique.

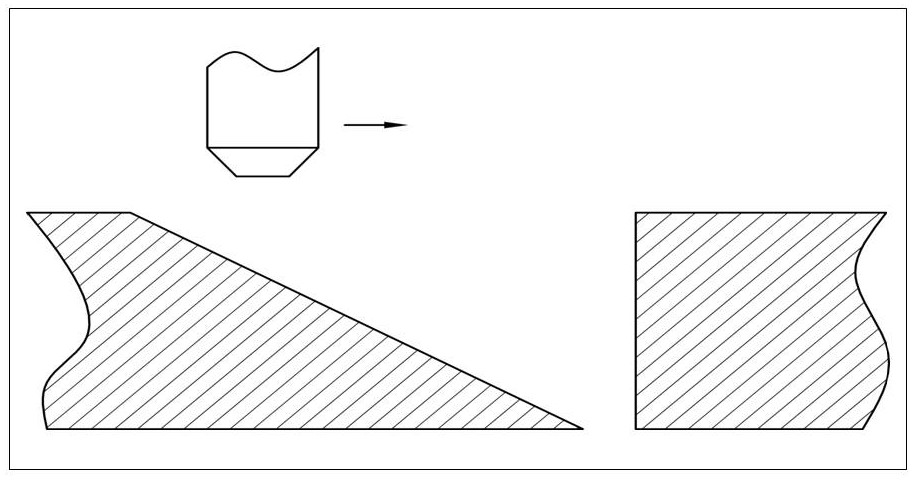

Moving Pierce Method

With the moving pierce technique, the torch is positioned over the plate some distance from the desired pierce point. Shortly after the plasma arc has transferred to the plate, the torch motion begins.

As the piercing process takes place and the torch moves, the plasma arc penetration depth increases, creating a trough that directs the molten material and sparks away from the torch, in the opposite direction of motion, instead of directly back at the torch (Figure 3).

Operators using this technique need to ensure their lead-in lengths are long enough to allow full penetration of the material. Operators also need to be extra cautious as a “rooster tail” of sparks can spray off the cutting table and potentially cause a fire.

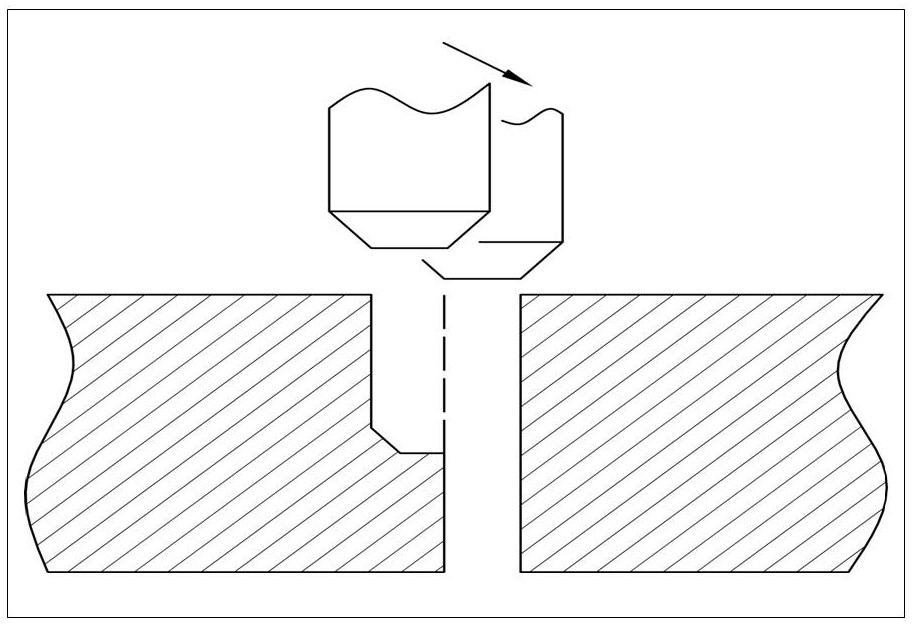

Double Pierce Method

The double pierce process starts by positioning the torch over the plate at the maximum transfer height of the system.

Continue the same process as with a stationary pierce, until molten material begins to spray back at the torch. This usually occurs when the pierce is about half way through the material.

Shut off the plasma arc, clean the slag from the plate and reposition the torch to the side of the partially pierced hole as though for an edge start. Finish the process by piercing a second time through the plate (Figure 4).

Because the torch is positioned at the edge of the partial hole, the molten material will spray away from the torch.

Although this technique can greatly increase the piercing capability of a plasma system, drawbacks include significantly larger pierce holes, increased material waste and much longer piercing times.

THE PHYSICS OF LIMITATIONS ON PLASMA PIERCING

All of this sounds good in theory. However, as piercing takes place and the hole becomes deeper, three limiting factors begin to impact the process.

The first factor is associated with the energy transfer to the bottom of the hole. This transfer of energy is reduced as the hole becomes deeper and the arc transfers its energy not only to the bottom of the hole but to the sides as well, enlarging the hole near the top of the plate and slowing the rate of pierce progression.

As the hole becomes deeper and wider, the distance between the torch and the work-piece lengthens, increasing the arc voltage and the chances of the arc going out.

Even if the power supply has enough voltage to maintain the arc, the longer pierce times mean the torch is kept over the hot molten steel for a longer period of time, which begins to melt the consumables, particularly the shield.

The second limiting factor is associated with the fluid dynamics of removing the molten material from the hole. Cold plasma gas and shield gas are supposed to blow the molten slag out of the hole and away from the pierce.

However, as the hole becomes deeper, this becomes more difficult. As a result, gas flow tends to puddle at the bottom.

The third factor limiting piercing of thick metals – and the one having the most impact – is the effect of the molten material coming out of the pierce hole. Much of it winds up on the end of the torch.

As the torch sits directly over the metal being pierced, heat and molten metal travel back to the torch. As the temperature of the torch – particularly the shield – increases, molten material more readily adheres to it.

This transfers even greater levels of heat into the shield, creating a continuously increasing condition of slag adhesion and heat buildup.

This progressive buildup of slag can block vent holes, block the main orifice and affect the torch’s initial height sensing; all of which negatively impact pierce capability and cut quality.

Eventually, the shield and even the nozzle can melt.

Another problem: Any molten metal that doesn’t wind up on the torch often winds up on top of the plate. This significant puddle, which usually forms on the top surface of the plate around the edge of the pierce hole, can cover a large area of the plate and be quite thick.

If the torch runs through this slag after it has begun to solidify, damage will occur to the tip of the torch (usually the shield).

Using a torch lifter with voltage control provides the ability to raise the torch over this puddle and prevent physical contact, but the action of raising the torch during the cut can cause striations in the cut edge as it passes through the slag puddle.

The best way around this problem is to provide a sufficiently long lead-in to the cut, preventing the torch path from crossing the slag puddle. As a general rule of thumb, a lead in equal to the material thickness being cut is usually recommended.

ADDRESSING THE LIMITATIONS OF PLASMA PIERCING

The first limitation to piercing thick metal plate or the energy transfer to the bottom of the hole is primarily addressed through the cutting system architecture.

The second limitation to piercing thick metal plate with regards to the removal of molten material from the hole, can be addressed through various piercing techniques.

Stationary piercing, low transfer/stretch arc piercing, moving and double piercing techniques can all help the removal process.

The third factor which limits the use of plasma to pierce thick metal – and, again, the one having the most impact – is primarily associated with the molten metal that gets blown onto the torch and consumables, especially the shield.

There really is no way to keep molten metal from hitting the torch. However, engineers from Hypertherm (Hanover, NH) discovered a way to keep the metal from staying there by reducing the metal’s tendency to stick to the shield by lowering the shield’s temperature.

They experimented with different cooling methods before coming up with a way to aim coolant at the part of the shield exposed to the most molten metal by employing a closed loop cooling system that directly contacts a flange on the back side of the shield.

During laboratory tests they used water as a coolant, controlling its temperature with a chiller/heater, and settled upon three different temperatures: 38 deg F, 85 deg F, and 135 deg F.

The testing involved piercing 1½ in thick mild steel plate with a HyPerformance HPR400XD system and using its 400 amp oxygen system to make 300 pierces.

The shield and shield cap were weighed prior to the start of the test and again after every 25 pierces to monitor the accumulated slag on the shield. This was done until all 300 pierces were completed. The test results were dramatic.

When the shield temperature was maintained (via the coolant) at 135 deg F, the sum of the slag through the duration of the test was 198 grams. At 85 deg F, the team saw a small but significant drop measuring 175 grams of slag after the 300 pierces.

The big change came when the shield temperature was dropped to 38 deg F. At that point only 31 grams of slag was measured.

Incorporating this technology (dubbed PowerPierce) into plasma torch and consumable design significantly extends the piercing capabilities of plasma.

The engineers estimate it is now possible to production pierce mild steel up to 2 in thick, opening up the benefits of plasma to more companies.

Specialized techniques can improve consumable life even further since a cooler shield also prevents issues with melting.

Advances such as this benefit companies who can now use plasma instead of slower or more expensive methods to expand their customer base and the work they are able to do.

Hypertherm, Inc., 21 Great Hollow Road, PO Box 5010, Hanover, NH 03755, www.hypertherm.com.