5-Axis Machining for Hard Milling Applications

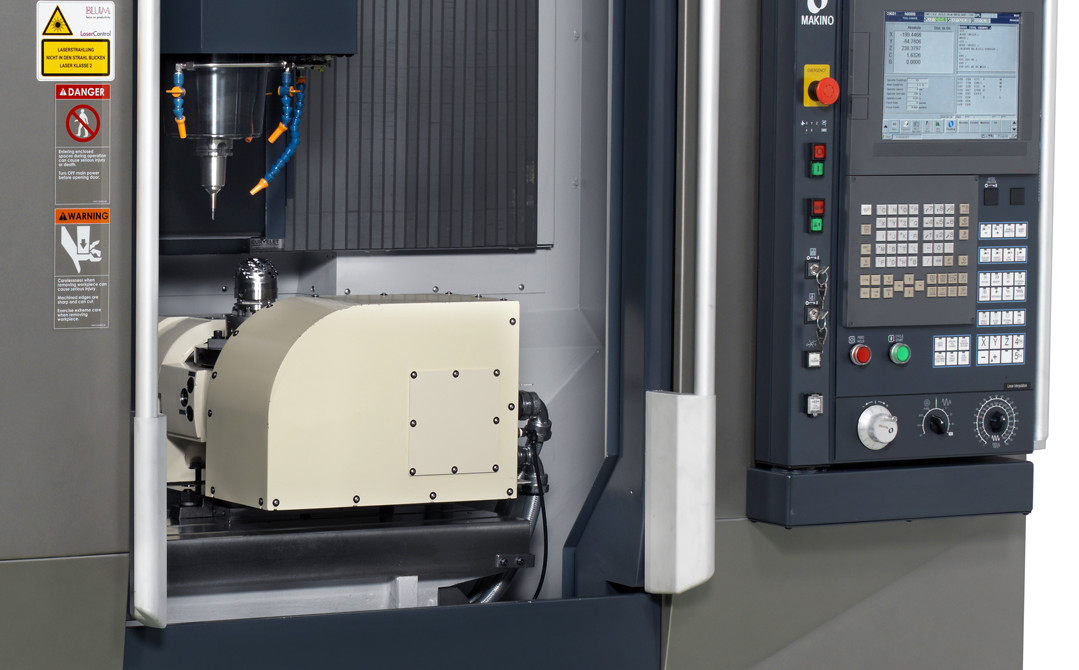

The F5-5XR vertical machining center from Makino provides five-face machining and full five-axis processing for complex, die/mold, aerospace and medical parts.

Posted: January 29, 2013

A highly productive 20,000 rpm HSK-63A spindle incorporates a patented core-cooling, under-race and jacket spindle temperature control system. The two-range spindle supplies unique, wide range capability with the stiffness and rigidity at lower ranges for roughing operations - and vibration, chatter-free production of small details and fine features utilizing small tools at high rpm. A 30 tool magazine provides capacity for a wide array of tooling.

(Click on photo to enlarge it)

The F5-5XR vertical machining center combines the speed, precision and flexibility required for tight tolerance, five-axis, hard-milling applications.

William Howard

Makino

"Using simultaneous five-axis, “2+3 machining” or even simple five-face machining techniques, the F5-5XR helps manufacturers reduce part set-up and handling, cut lead-times, improve quality and lower costs – while providing outstanding precision and fine finishes in very demanding, complex, 3D contoured part applications."

(Click on photo to enlarge it)

The rotary table uses a dual taper, double disc braking mechanism that generates higher clamping torque for both the tilt and rotary axes, supporting heavier cutting forces in hard materials while maintaining precise positioning accuracies with a repeatability of ±2 arc seconds.

(Click on photo to enlarge it)

The F5-5XR vertical machining center provides five-face machining and full five-axis processing for complex, die/mold, aerospace and medical parts.

The F5-5XR vertical machining center from Makino (Mason, OH) combines the speed, precision and flexibility required for tight tolerance, five-axis, hard-milling applications. Based upon the F5, the F5-5XR is an affordable five-axis solution for complex, die/mold, aerospace and medical parts.

“The F5-5XR offers the same speed and precision of the F5, but with the added flexibility inherent to five-axis machining centers,” says William Howard, the vertical machining product manager at Makino. “Using simultaneous five-axis, ‘2+3 machining’ or even simple five-face machining techniques, the F5-5XR helps manufacturers reduce part set-up and handling, cut lead-times, improve quality and lower costs – while providing outstanding precision and fine finishes in very demanding, complex, 3D contoured part applications.

The F5-5XR provides X-, Y- and Z-axis travels of 35.4 in, 19.7 in and 17.7 in, respectively, the 39.4 in by 19.7 in machine work table provides ample room for the 5XR table and workpiece arrangement as well as additional table space for a vice to accommodate other non-five axis work and an optional laser Automatic Tool Length Measurement (ATLM) system.

The F5-5XR’s new rotary table design offers advanced performance with increased speed, accuracy and power. Its compact design provides an expanded work zone over previous rotary tables, facilitating larger workpieces.

A dual taper, double disc braking mechanism generates higher clamping torque for both the tilt and rotary axes, supporting heavier cutting forces in hard materials. This table design also offers improved productivity through increased tilt and rotary speeds, while maintaining precise positioning accuracies with a repeatability of ±2 arc seconds.

Included in the standard configuration of the F5-5XR is a highly productive 20,000 rpm, HSK-63A spindle which incorporates Makino’s patented core-cooling, under-race and jacket spindle temperature control system. The two-range spindle supplies unique, wide range capability with the stiffness and rigidity at lower ranges for roughing operations – and vibration, chatter-free production of small details and fine features utilizing small tools at high rpm. In addition, a 30 tool magazine provides capacity for a wide array of tooling.

The F5-5XR utilizes the Makino Professional 5 Control which affords the perfect blend of a Windows CE graphical user interface (GUI), touch-screen selection offering instant access to information literally at your fingertip, user-friendly, efficient PC-like capability for data management and editing and the networking and storage capability of a data center.

Also featured in the F5-5XR is Makino’s proprietary, next generation Super Geometric Intelligence (SGI.4) software – developed specifically for high-feedrate, tight tolerance machining of complex, 3-D, contoured shapes involving continuous tiny blocks of NC data insures production rates faster than standard CNC systems while maintaining high accuracy. SGI.4 helps provide the lowest cycle times and costs achievable by reducing machining cycle times on dies, complex cavities and cores and medical parts by as much as 40 percent when compared to most other control technologies.

A world leader in advanced CNC machining centers, Makino is committed to providing high-performance, leading-edge machining technologies and innovative engineered process solutions that enable manufacturers to focus on making what matters. The company offers a wide range of high-precision metal-cutting and EDM machinery, including horizontal machining centers, vertical machining centers, 5-axis machining centers, graphite machining centers, and wire and Ram EDMs. makino.com