Hard Gaging Goes Soft

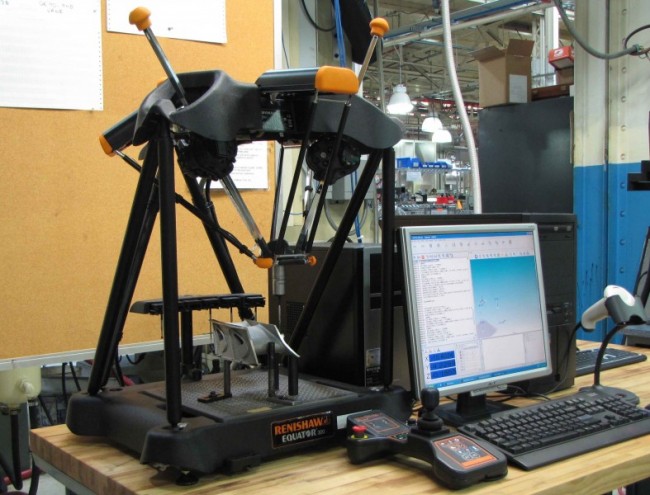

Jet engine component maker Meyer Tool reduces its hard gage costs by replacing multiple costly hard gages with a single software-driven Equator gage from Renishaw.

Posted: November 5, 2012

One software-driven comparative gage is already starting to soften up the cost for numerous hard gages at aero-engine component maker Meyer Tool, Inc. (Cincinnati, OH). In its pre-launch application, one Equator® gage from Renishaw Inc. (Hoffman Estates, IL) eliminated at least four costly hard gages in a new work cell. And that is only the beginning of the impact this company anticipates for its inventory of custom hard gages, which can cost up to $20,000 each to design, build and maintain.

Meyer Tool is a leading U.S.-based producer of hot-section jet engine components for aerospace OEMs, employing more than 1,000 at ten locations. One of Cincinnati’s ten largest private employers, the headquarters specializes in new parts while some other Meyer facilities do repair and overhaul for the OEMs. Principal workpiece materials are super alloys, nickel and cobalt-chromium based.

With nearly 500 fast-hole EDM drillers, Meyer Tool is North America’s largest EDM-based manufacturer. These machines are supplemented by 45 grinding stations, 300+ conventional ram EDMs, plus 3-axis and 5-axis CNC machining. The company EDM-drills more than 1.75 million holes per day. With one blocked hole out of hundreds capable of causing failure on military high-pressure blades, the organization is fanatical about quality.

The company employs 10-15 quality engineers, eight Black Belts, and a statistical process control (SPC) team of five. “We began implementing lean principals more than ten years ago, followed by AS9100 certification,” recalls Beau Easton, the quality manager at Meyer Tool. “The investment has paid off, too. Our first time yield rate for January 2011 is 98.9 percent – that is, first time off the machine without non-conformance or reject.” He adds that this was accomplished by getting real-time feedback “turned up” to a much higher level.

The information backbone of the company’s gaging, SPC and quality system is its own Orion software and workstations, sold commercially through its subsidiary, Sigma Technology Services. All parts are 100-percent inspected by various means, including laser scanning and touch probing on CMMs, 5-axis vision, radiometric measurement and flow path scanning, among others, all of which are networked on the Orion system which serves as a common operator interface on measurement systems.

Measurement programs, results and SPC data are managed by the Orion system. When a machinist completes an operation on a part, its serial number is scanned into the system, the part is measured, and the machinist can immediately see the results and compare them with the last 35 similar parts that have been measured. “You can scan a part’s serial number into any terminal in our plant and see its measurement data,” says Easton. “This information stays with the part. Before it ships, all inspection data is checked that all points passed, and any failed point kicks the part out until it passes all checks. As a result, our ppm ‘escape rate’ is almost non-existent . . . and customers recognize this.”