Tackling the Tough Traits of Tubes

Want to eliminate all of the milling, drilling, cluster punching, coping, set-up and handling that comes with fabricating deformed, bowed and twisted tubing? Consider laser cutting.

Posted: August 16, 2012

If you are one of the lucky ones who commonly use tube and pipe in your fabrication processes and suffer the frustrations of dealing with deformed, bowed, twisted tubing and the infamous non-uniform radii, fear not – there may be a solution! The use of tube in the fabrication world has grown in popularity due to its strength and relative light weight. Yet, as those who work with tube know, processing it can prove to be quite difficult. Inconsistencies in manufacturing, poor quality control and inappropriate storage and transfer techniques all lead to defects causing processing issues further down the production line.

And with material cost always a concern, your purchasing manager most likely has not invested in the best quality tube available. With tube being produced globally, you often find last week’s bundle looks nothing like the lot you received today, even though you ordered the same size tube from the same supplier. Regardless of the reason, working with tube is widely recognized as a challenge.

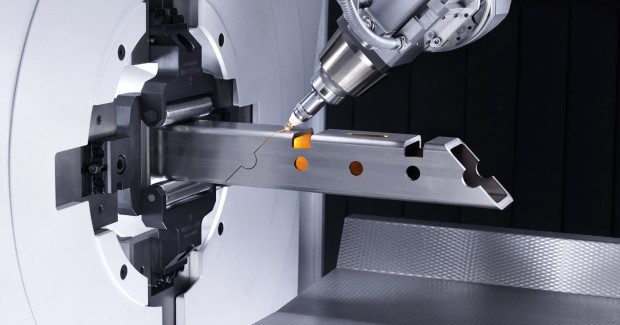

Modern advancements in lasers for manufacturing have led many fabricators to use the technology for tube processing. At the moment, there are more than 300 dedicated tube cutting laser systems in North America. The positional accuracy, high processing speeds and superior edge quality from the laser attract many fabricators. The ability to eliminate several other processing steps such as milling, drilling, cluster punching, coping, all the set-up and handling, as well as saving floor space for work-in-process make laser cutting of tubes the obvious choice for many manufacturers.

Time consuming actions such as the re-machining of mandrels and the building of jigs can be eliminated. The ability to simply add tabs and locking joints prior to welding guarantees proper tube-to-tube location. This enhances structural integrity, simplifies final assembly and minimizes scrap. Looking at some of the typical inconsistencies found with tubing and problems associated with its use in fabrication, we can see how laser machine tools of today offer solutions to overcome the tubes’ shortcomings.

BENT TUBE COMPENSATION

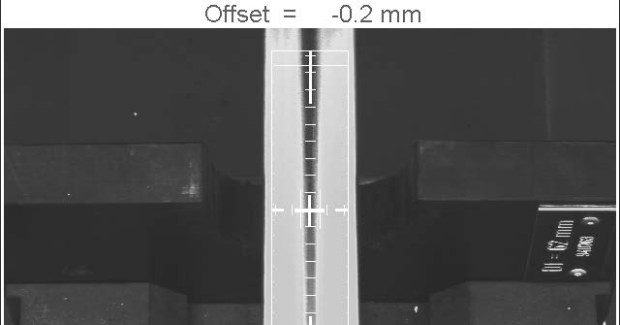

Many dedicated tube processing laser systems now offer solutions to correct the handicaps that result from bent tube. For some, the solution is a touch pendant which comes into contact with the sides of the tube to calculate a new centerline for accurate hole and cutout positioning. Others offer an elaborate multi-point measuring sequence using the sensitive cutting head itself. Here the cutting head’s nozzle measures one or two locations on the adjoining sides of the face you are about to work on. The measured points are then used to recalculate the new center offset position of the face.

Another technique measures the adjoining corner positions at the beginning of the radii once again using the capacitive height sensing device and the nozzle. The result is a hole or feature that is positioned correctly on each face, as designed.

MATERIAL TWIST

Another calculation that may be performed during a measurement cycle can correct for twist in the tube. Measurements of two points on the surface that you are about to cut can be made across the breadth of the face. The height difference between the two is recognized and the tube is rotated to compensate; adjusting so it becomes truly horizontal at that location. It is important to remember that both bow and twist in the tube is rarely uniform and repeated measurements are often necessary. Although these calculations take precious time they typically account for only a few seconds per measurement set. However, if the tube is of very poor quality, many measurement cycles may be needed.

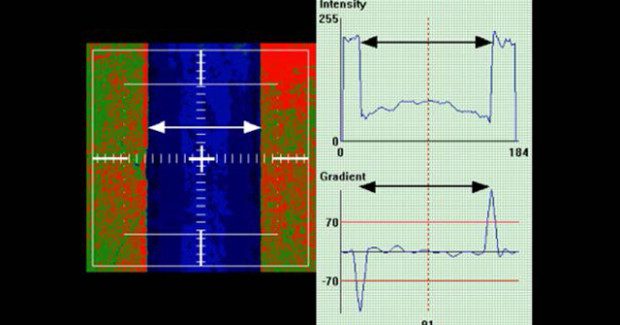

WELD SEAM SENSING

One would expect there to be greater consistency in weld seam positioning on tubing, yet this is not the case. Tube manufacturers are free to position the seam wherever their customer wants it, resulting in apparent inconsistencies. Luckily, most laser tube cutting systems today have the ability to detect weld seams and quickly reposition the tube. This ensures holes and other cut features are positioned on the tube so as to avoid deformities later when the tube is formed or bent. Positioning the weld seam is also helpful for fabricators looking to hide the weld and minimize its visibility for cosmetic reasons, such as in manufacturing of furniture or display cases.

Most tube laser processing systems offer optical sensing cameras that detect contrast in color where the weld seam is located. Though this works for most tube, the sensors can only identify fairly sharp contrast or visible welds. The more difficult it is to see, the more difficult it will be to detect. Other types of detection for weld seams, such as magnetic and eddy-current detection, may be available for integration but are often cost prohibitive or difficult to implement.

TIGHT TOLERANCES: REMEMBER “YOU GET WHAT YOU PAY FOR!”

When visiting customers I often see the materials operators are given to be processed. Even when the designer specified tolerances within a few thousandths, the tubing they intend to use is of poor quality. I have seen tubes with inconsistent sidewalls: convex, concave or a combination of both. Or corner radii that are double the size on one corner compared to the others. Often, I have seen tubes that have been stored such that severe bowing results or rusted from being stored outside for weeks (lasers are not fond of rust by the way!). And everyone expects finished part accuracy. As a general rule, if the tolerances for the assembly are tight, better quality tube should be used.

Until tubing becomes more consistent in their construction and it is stored and shipped properly to minimize deformation, realize that tube cutting laser systems are often the best technology to correct these real world challenges. By working with customers and educating their designers on the possibilities lasers afford, new “smart” tube designs can be easily created. Cost saving assembly simplifications can be easily achieved so that processing tube no longer is a frustration but simply a wise manufacturing solution.