Robotic Work Cells Help Diversify Business

Take a look at how contract manufacturer K-zell Metals can diversify and compete against global competition by bidding and planning fabrication work more aggressively with its increased capabilities and automation flexibility.

Posted: May 15, 2012

“With the military work we’re doing, I really don’t have any desire to go to a war zone to fix a reject,” smiles Kammerzell. “We need to make sure the parts we produce are right initially. If we design the fixtures properly, then do the welding correctly so that the part stays in the fixtures, they really become self-checking because we know we have them dimensionally accurate because the fixtures were accurate. When the parts come out, they are going to stay that way. This eliminates an awful lot of our inspection time because we ‘design in’ the inspection when we build the fixtures.”

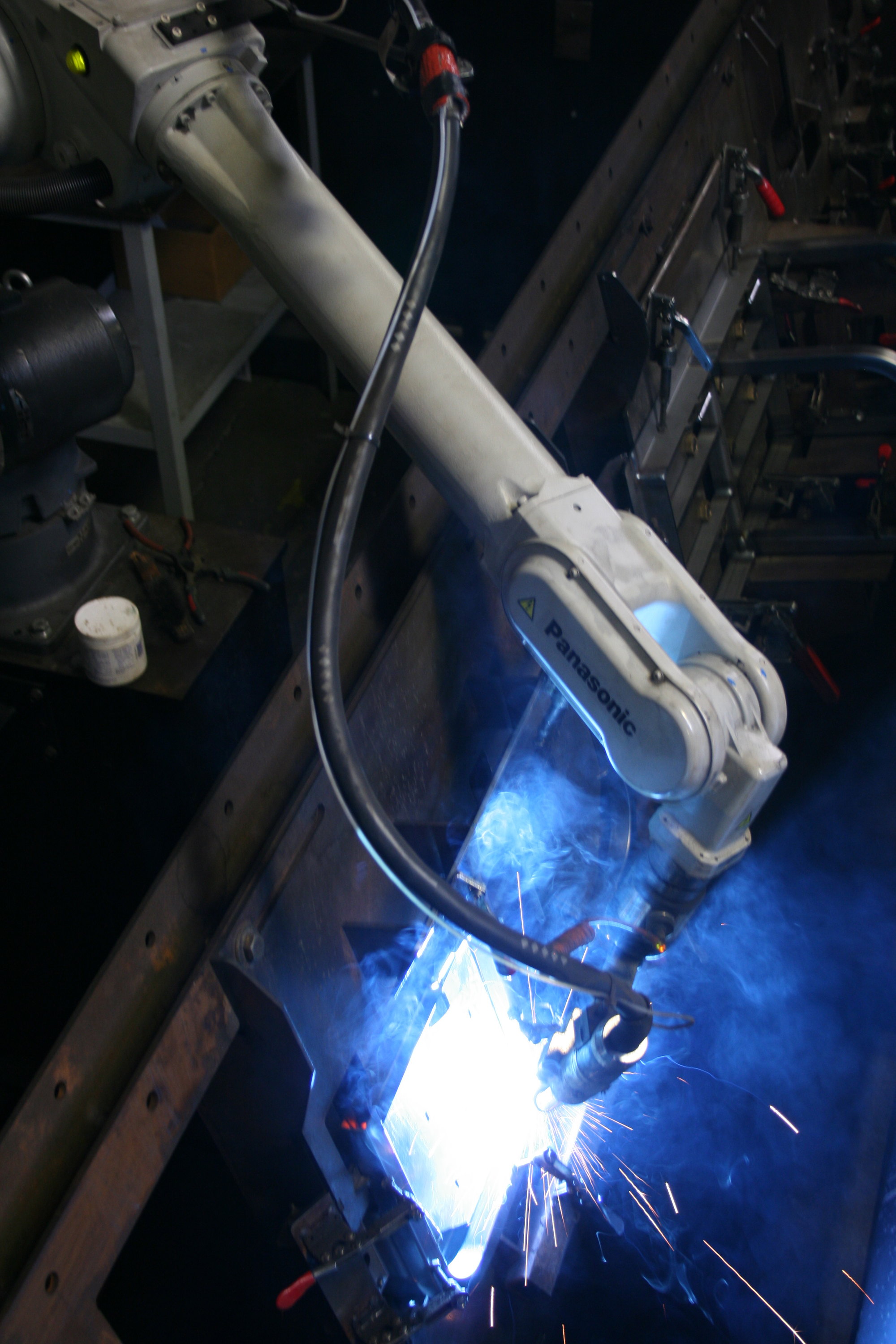

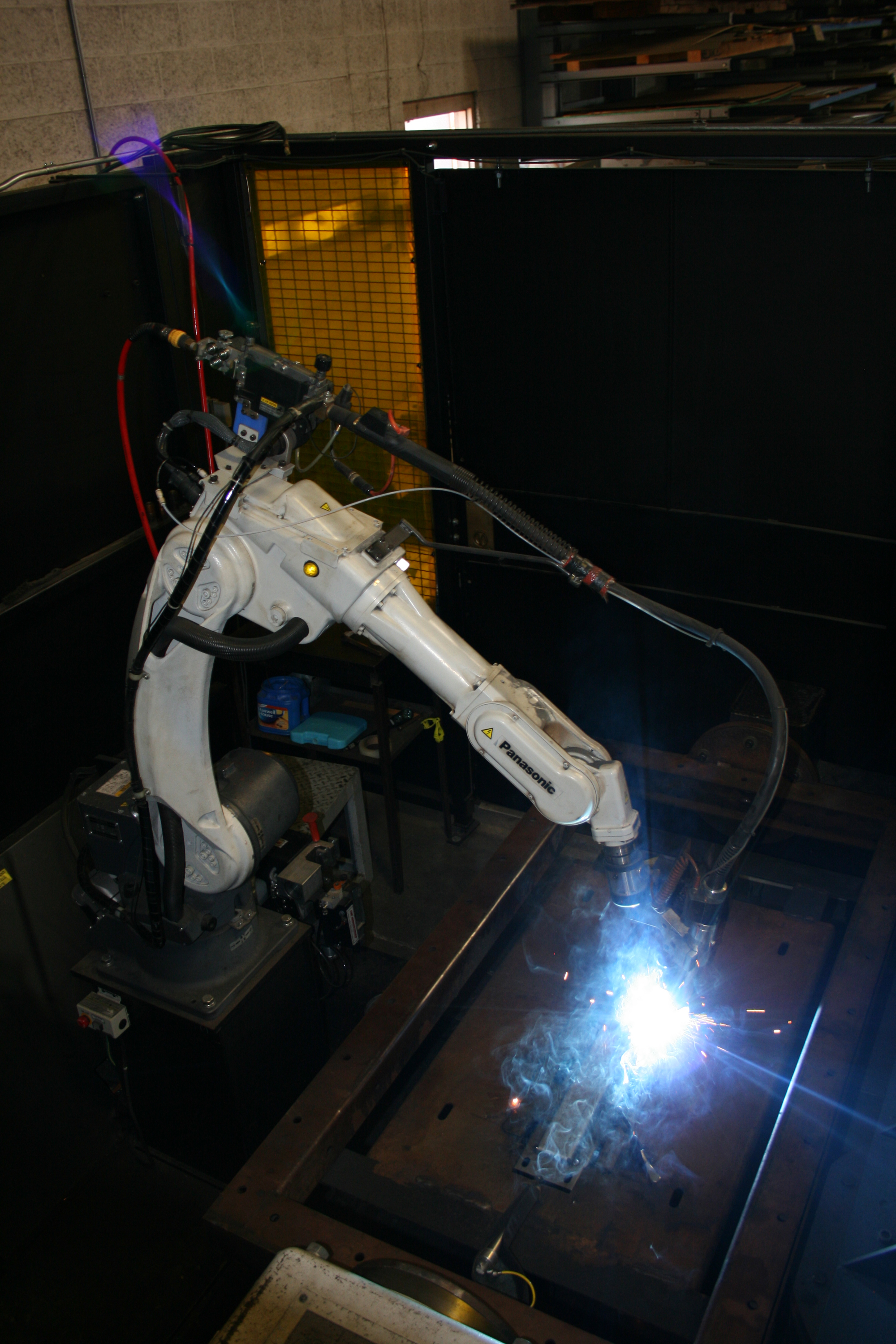

Many robotic welding applications stumble because of inefficiencies in upstream processes that lead to incorrectly sized parts and poor fit-up. This awareness can actually be a benefit: If you are unable to consistently get the same result with a robot, there are adjustments that may need to be made upstream in the process.

“The robotic weld cell forced my laser guys and my press brake guys to be more on their toes in getting work done right because they’re automatically checked every day,” states Kammerzell. “The parts have to be right because they must fit in the fixtures. This builds in more quality to the process.” Driving out that variation ultimately leads to reduced failures, rework, and scrap. If a part is done right the first time, productivity moves forward. If it has to be redone, that’s a step backwards. Being able to reduce factors such as spatter and distortion and more accurately control weld parameters ensure the greatest quality.

“To reduce the spatter in a welding operation, whether it’s manual or robotic, you need to make sure you’ve got your parameters set right,” explains Kammerzell. “It’s a lot easier with the robot, especially with some of our parts where we’re changing directions after an inch of weld and we’re doing some things that it’s very difficult for a man to repeat every time. That’s what the robot is designed for. We’ve been able to reduce the spatter in a number of areas much (more) than we were able to do it manually.”

That reduction in spatter helps reduce rework and also helps reduce costs in other downstream activities. “The reduction of spatter really matters on the military components we’re doing because most of those parts have a sophisticated coating system on them,” notes Kammerzell. “You can’t have loose BBs rolling around. So the reduction in spatter reduces the cleanup time there and makes the coatings go on better, which means we have less cost in applying the coating.”

The more precise control over parameters provided by a robotic weld has also helped reduce distortion and over-welding. Controlling over-welding not only improves part quality, but helps lower gas and consumable use related to laying down too much weld material. “Distortion is a very significant issue to our customer because a lot of our parts are subassemblies that need to assemble into a finished product,” says Kammerzell. “If our dimensions are just a little bit off, we’ve got a problem there. Over-welding is really an issue in some of the parts. If you over-weld it, then you have to do too much grinding to get it back down to where the parts fit together. Reducing over-welding is a significant issue.”

PRODUCTIVITY ENHANCEMENTS JUSTIFY ROBOTICS

Overall, the system has led to a number of efficiencies, including ease of installation, the seamless integration into the shop workflow, simplified programming that doesn’t slow production, and a reduction in spatter, rework and scrap. As with any system, however, the bottom line is the ultimate judge of its total effectiveness: Can you produce more products while meeting or exceeding your customers’ quality standards?

“What we found to be really competitive was that our fixed overheads, such as building rent, all stayed the same but the amount of throughput we were able to push through the robotic cells really lowered our costs,” states Kammerzell. “When we looked at doing the robots, during the first cell we put in we said ‘ok, let’s plan on getting a 15 to 20 percent increase in productivity.’ We were able to do better than that when we did begin production, which meant we were able to reduce our customer’s buying price and reduce our costs down to where our profit margins were able to stay where we wanted them.”

And that, he adds, translates into a return on investment: “We’ve definitely seen the ability of the robot to pay for itself. Because of the contracts we were able to find, they paid for themselves significantly faster than we anticipated . . . within two years.”