Robotic Work Cells Help Diversify Business

Take a look at how contract manufacturer K-zell Metals can diversify and compete against global competition by bidding and planning fabrication work more aggressively with its increased capabilities and automation flexibility.

Posted: May 15, 2012

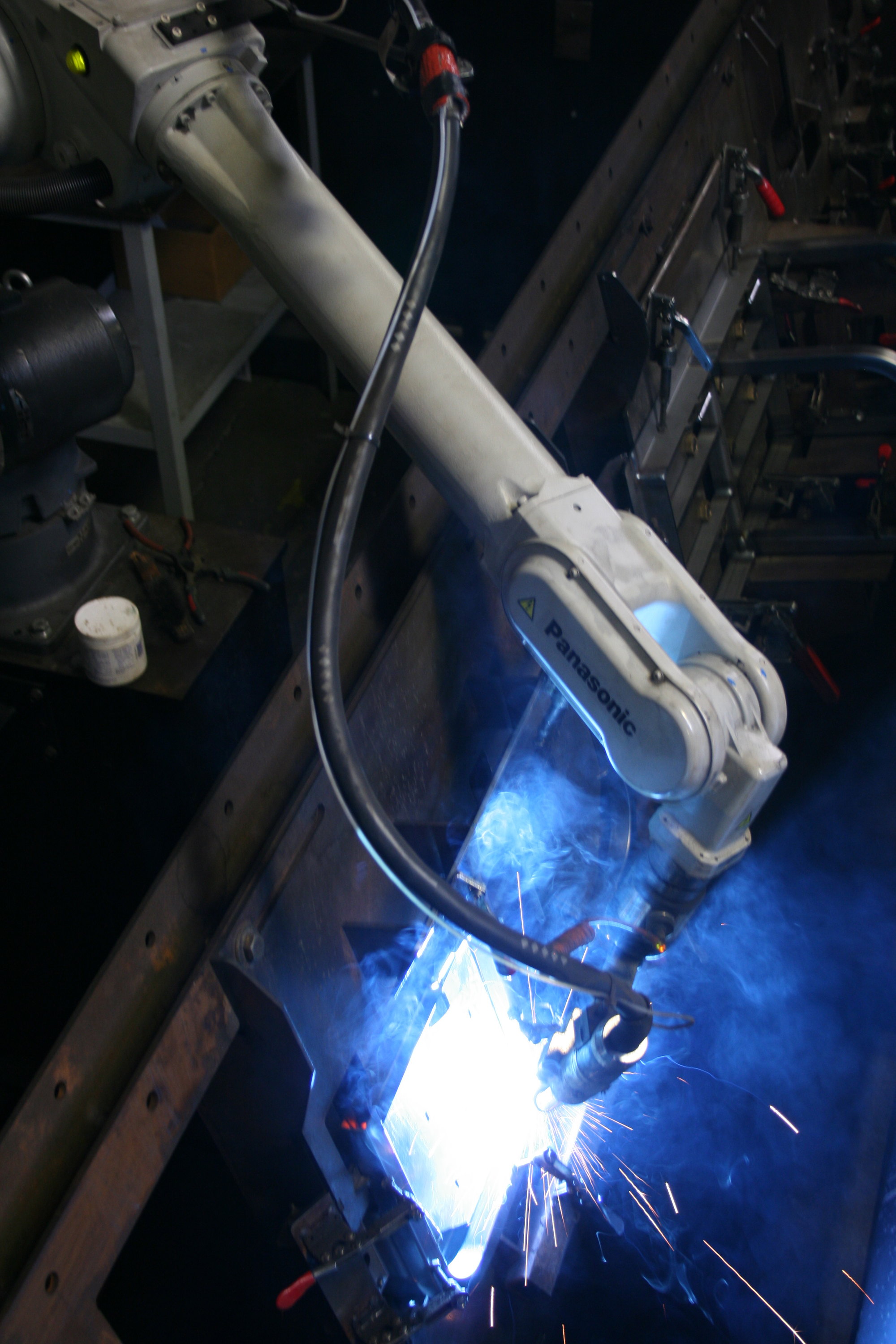

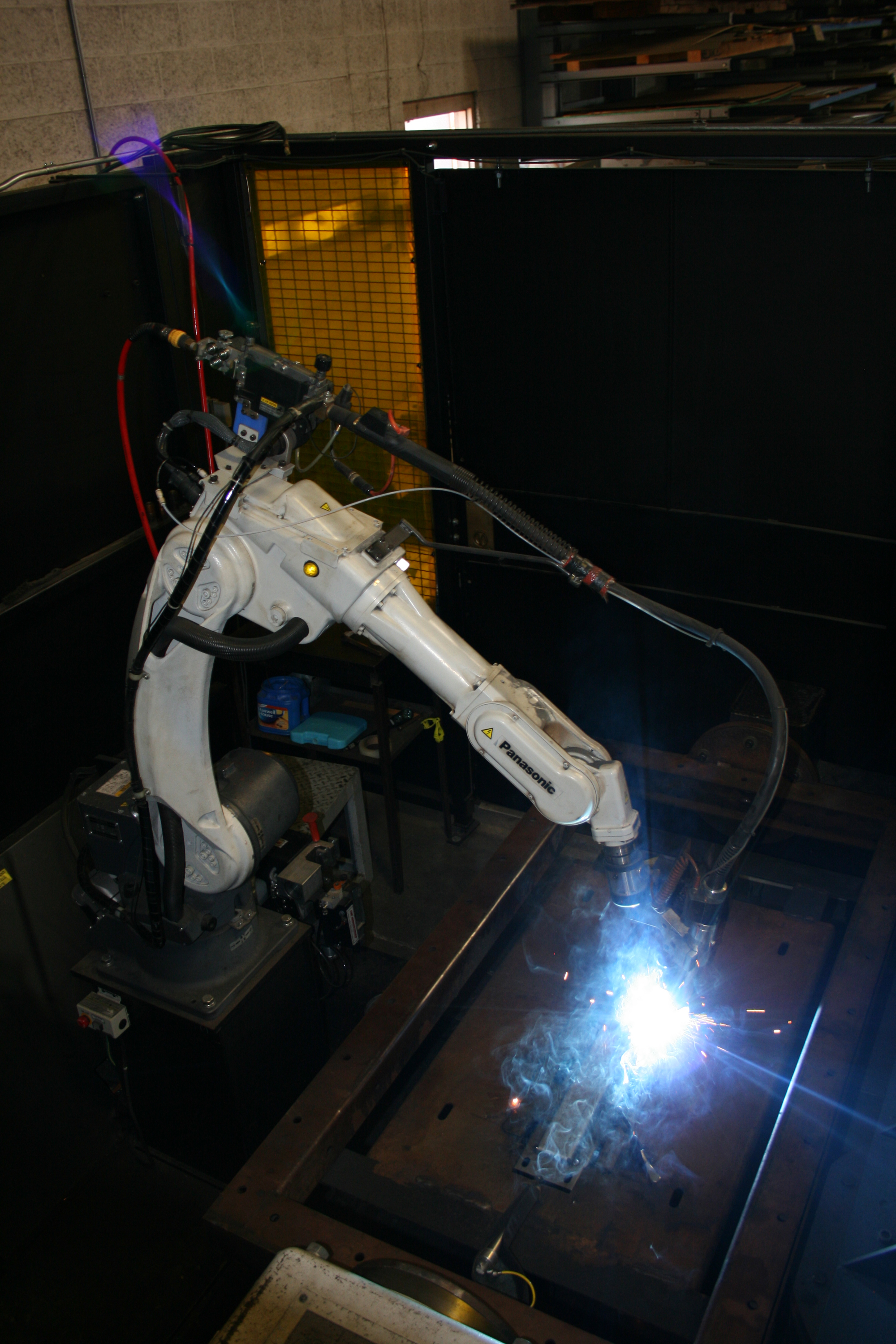

Pre-engineered weld cells can be dropped into existing workflows and put into operation with much of the basic tooling that manual welders are already using. With three mechanical engineers on staff, K-zell builds all of its own quick-change tooling and fixtures, a skillset that helps the shop adjust to product runs of all sizes and quantities. Each cell features a fully welded frame and comes pre-wired and pre-assembled (the PA 1100 FW comes in three sections that can be joined with quick assembly and connection capabilities). The cell is completely integrated and can be easily relocated by disconnecting the utilities and moving it to a new location.

“One of the primary advantages to us was lead time,” notes Kammerzell. “We were able to order the equipment and knew that we were going to have the cell come in and sit on the floor and we could get going with production right away. We looked at the ease of programming and found that this system was much easier to program than the robotic cells we had looked at previously. And then we looked at the ability to eventually go to offline programming.”

According to Jim Benjamin, the quality assurance manager and robotic welding supervisor at K-zell Metals, the design of each cell allows for nearly 100 percent robot run time. The positioners on both the PA 1100 FW (Ferris wheel style) and the PA550 HW (merry-go-round style) create a two-station weld cell. “You have a man loading one part on one side while the robot is working on the other side,” he says. “This is a continuous arc-on situation. As soon as the table flips out, I’m unloading and loading a new one into the robot, but it’s still working at the same time.”

Kammerzell emphasizes that the design of the cell, with the work being done away from the flow of the shop floor, was an important factor. “The work flows by the cell,” he says, “and it stops just for a moment then moves on. It is less of an impediment and more of a sidebar to the flow of work through the shop.”

OFFLINE PROGRAMMING MOVES PARTS TO PRODUCTION FASTER

One of the key factors that allows K-zell to move parts into production faster is offline programming. Using Desktop Programming and Simulation (DTPS) software to sequence operations offline allows this shop to program its robot from a computer rather than on the robot itself, eliminating downtime. Upon completing all of the weld sequences, the system lets the welding program run as a simulation so the software can detect possible collisions, identify areas where weld procedure angles could be difficult to achieve, and provide the time it would take for the cell to make a complete part. Only minimal touch-up is required in the cell with the teaching pendant once programmed.

“One of the things that we obtained with these robots were the solid models of the robot cell itself so that we were able to design our fixtures in SolidWorks,” explains Kammerzell. “We can marry our robots, fixture tables and parts all in one model. Then, using offline programming, we’re able to program the welds and make sure that the fixture will work before we get it down in the shop. This means we can build a virtual model of everything, run through it, make sure all the welds will fit and get gun access to it. This has made a huge difference in how fast we can get parts into the robot.”

“This is a very streamlined application once it gets to the floor,” states Benjamin. “A very quick turnaround. We don’t have to stop our current production load. We may have 100 parts to get out today, but tomorrow there might need to be a different part coming through that robot. So we can get a lot of work done prior to actually hitting the shop floor.”

PROVEN IMPROVEMENTS IN QUALITY

The primary goals of a robotic system are to drive out variation, increase throughput, reduce the amount of non-value-added activities in the welding process and ensure the total quality of each part. For K-zell, considering where many of its products go to work, this is exceedingly critical.