Resistance Spot Welding of Aluminum Moves to Production Line

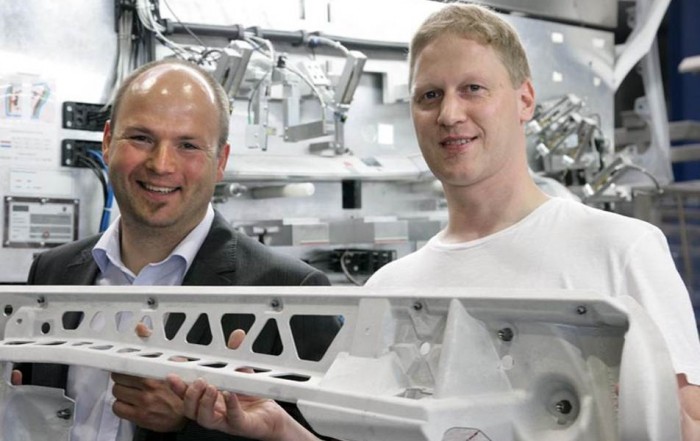

Georg Fischer Automotive uses an innovative resistance spot-welding process from Fronius to join die-cast aluminium parts in the vehicle door-frame on the Porsche Panamera.

Posted: May 16, 2012

A third and very significant advantage of this process is the scope that it gives for systematically influencing the heat balance in the workpiece. The result is more heat in the workpiece at the same time as lower electrical input power. The process tape can be used as a flexible tool for creating optimum conditions in each case, e.g. for joining materials of different compositions and thicknesses, or for multisheet joints.

BOUNDARY CONDITIONS

The four different doors of each set have to have inside stiffeners spot-welded to them. The doors are made of die-cast aluminium, each weigh 4.5 kg and are furnished with a titanium-zirconium (TiZrSiO4) anti-oxidation layer. “On the weldment, there is a main seal between the door and the frame at the point that has to be joined. This means that the welding carried out here must be as spatter-free as possible. The thermally induced distortion on the workpiece has to be kept within tight limits, and we have to be able to cancel it out with subsequent straightening”, explains Hintsteiner. “These are all reasons why conventional resistance spot welding is unsuitable. Firstly, because it causes too much spattering, and secondly, because its uncontrollable and very intense point-focused thermal input risks badly distorting the metal sheet around the weld-spots. Unlike large-area shape-distortion, this is a defect that cannot subsequently be corrected, which means that the whole door, with its unsightly undulating surface, is then only fit for the scrap bin.”

Because of the extremely high dimensional accuracy required on the outside flange, clinching and punch riveting were not viable options either. The main exclusion criterion here was the shape-distorting action of mechanical forces. Punching and riveting at such close-spaced intervals in the workpiece would cause kinks and undulations which would mean an unacceptable degree of surface unevenness. Adhesive bonding, and combinations of bonding with other joining processes, were also disqualified. Although adhesive-bonded joins are made without impairing the shape of the workpiece, they cannot be subjected to loading while they are curing, and the adhesive would cause unacceptable surface contamination.

Friction-stir welding also failed to make the grade, remembers Hintsteiner. “For our application, it was simply inferior to joining using DeltaSpot, from the production-engineering point of view. The reason is that in friction-stir welding, you have to allow for the overall wall thickness of the parts. Because of the casting tolerances, we would have had to ascertain and key in the exact thickness of the parts to be joined before every single welding operation, which would hold up the production process for too long.”

BENEFITS AND USEFULNESS

DeltaSpot has now proved its merits in everyday production-line practice since 2008. “The machine runs with complete process-reliability,” reports a very satisfied Edtbauer. Hintsteiner lists some features of the application that are particularly relevant in terms of user benefit. “The process tape lets us produce a uniform, exactly replicable spot that is exactly 5 mm in diameter, and with 16 spot welded joins on every workpiece,” he says. “We weld one of these doors in an approximately 100 sec cycle, after which we don’t need to do any finishing-work on the surface. As far as the appearance is concerned, we’re getting a very clean weld spot. It takes less than 15 min to change the process tape, and this only has to be done after about 5000 weld-spots, which means that we can weld around 300 Porsche Panamera doors without interruption. Every day, we produce all four doors for 185 Panameras.”

The electrodes only need changing once per tape. By way of comparison, in suitable conditions users would only be able to weld 20 spots using conventional resistance spot-welding. In effect, this would mean cleaning the electrodes once for nearly every door! “We work round the clock, that’s 15 to 16 shifts per week,” notes Edtbauer. “The DeltaSpot process creates a strong join between the two components without any difficulty – it only exerts minimal mechanical force and doesn’t need any extra mechanical materials. In our area of use, we’ve found it to be very cost-effective.”

CLIENT REQUEST, PRODUCT PROSPECTS

Based on the goals that have been reached and on their positive experience of the system so far, Hintsteiner has come up with some more features he’d like to see implemented. “Being able to keep a sort of log of all the spots that are welded, identifying which door each spot was welded on, would be helpful for our quality documentation,” he says.

Both experts are very positive about the prospects for DeltaSpot. “For applications like ours, with weldable castings, a defined surface, an anti-corrosive coating and adequate accessibility, DeltaSpot is the system of choice,” Hintsteiner. “Now we can offer our clients an alternative production step for applications like these, and this gives us a competitive edge.”

Fronius USA LLC, 10421 Citation Drive, Suite 1100, Brighton, MI 48116, 810-220-4414, Fax: 810-220-4424, [email protected], www.fronius.com.