Estimating Total Welding Costs

Keeping your welding costs low goes far beyond buying the lowest priced wire available. You must analyze how welding processes that increase deposition rate and increase productivity will reduce the largest component of welding costs – your labor and overhead. Here’s how to do it.

Posted: April 25, 2012

Q: In order to keep welding costs as low as possible, shouldn’t I just select the lowest price wire available?

A: There are several factors that need to be considered when determining the overall cost of welding. Of course, the most obvious factor is the cost for the consumables (electrode and shielding gas or flux). The less obvious (and frequently overlooked) cost is the labor and overhead expenditure that can be allocated to the actual process of welding.

However, as will be shown in our example, the labor and overhead portion of the actual cost of welding is generally between 60 percent to 70 percent of the total cost. So selecting an electrode that improves productivity (by increasing deposition rates) is far more important that selecting an electrode with a lower cost. A process to determine the total costs of welding will be outlined below.

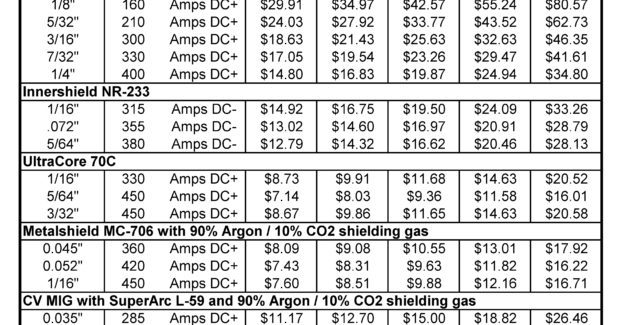

Using an arbitrary $50 labor and overhead rate and the “market list price” for a wide range of welding consumables, an estimation of the cost for one pound of deposited weld metal is listed in Table 1. Five different operating factors were used (the lowest being 20 percent and the highest 60 percent), where operating factor is defined as the percentage of a welder’s time that he is actually welding. For the GMAW, FCAW-G and MCAW processes, a rate of $0.20 per cubic foot was used for shielding gas costs.

In addition to labor, electrode, and shielding gas costs, the charge for the electricity needed to power the welding machines was incorporated into the total welding costs. Although in our example the cost of electricity per pound of weld metal never exceeded $0.40, this value is not insignificant and therefore was included in the calculations. On average, the cost for electricity was determined to be about 2 percent of the total welding costs when a $0.20 per kilowatt-hour rate was utilized. No “demand charge” pricing structures were used.

Complicating the selection of the most economical welding process (FCAW, GMAW, SMAW, etc.) and the right welding electrode (wire or stick) is the available equipment within the fabrication shop. If the highest output power sources presented to the welder happen to be 450 amp, 60 percent duty cycle machines, then the answer to electrode selection may not be as simple as “let’s use the largest wire diameter available to get the highest deposition rates.”

For example, in Table 1, the costs per pound for UltraCore 70C are shown and indicate that it is more economical to use 5/64 in diameter than it is to use 3/32 in diameter (at 60 percent operating factor the cost per pound of weld metal is $7.14, versus $8.67). This is because at 450 amps, the deposition rate for 5/64 in diameter UltraCore 70C is greater than that of the 3/32 in diameter, due to its higher current density. However, had we been able to fully exploit the full amperage range of the 3/32 in wire (with the maximum output amperage being around 700 amps), we would have seen the 3/32 in diameter wire provide a cost advantage.

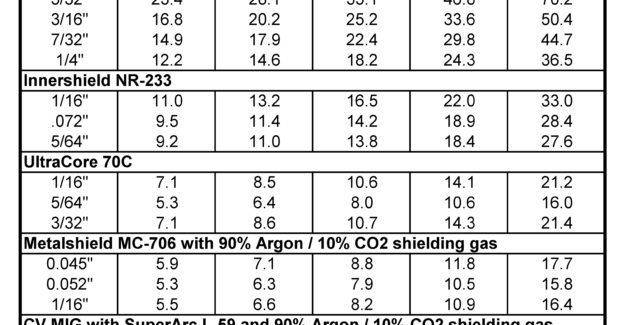

So for our calculations, the welding current used was either the highest amperage value in the range provided for the electrode, or the maximum output for the welding machine (450 amps). From this amperage a deposition rate in pounds per hour is determined, and then the total welding time for one pound of deposited weld metal can be calculated. This time to deposit one pound of weld metal is listed in Table 2. At this point, the labor and overhead cost required to deposit that pound of weld metal can be determined by multiplying this time value by the stated labor and overhead rate of $50 per hour.

In addition to using a 450 amp multi-process power source for the potential “open arc” welding processes being considered, we also have an additional resource in the form of a 1000 amp AC/DC submerged arc welding power source. Although operating factors approaching 80 percent or more are possible with submerged arc welding, we will limit the operating factor at 60 percent for the basis of comparison to the open arc processes. However, we will make full use of the maximum 1000 amps available on the machine, as this aligns nicely with the maximum recommended current for 5/32 in submerged arc wire.

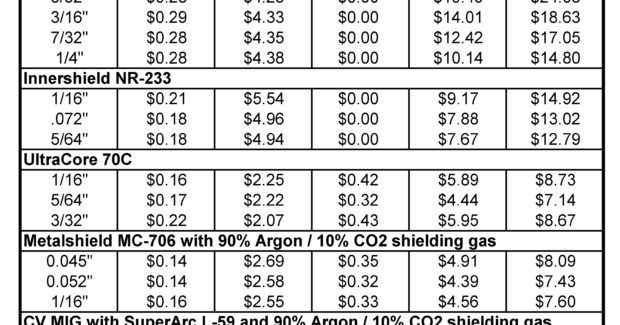

Based on the constraints that we have set, the components of the total welding costs (at an operating factor of 60 percent) have been separated out for the potential welding consumables under consideration in Table 3. For an E7018 stick electrode, the labor and overhead portion of the total welding cost comprises anywhere between 69 percent to 85 percent of the total welding cost. On the opposite end of the spectrum, the labor component makes up only 32 percent of the total welding cost for the submerged arc welding process at 1000 amps. And finally, for the wire-fed processes, the labor component of the total cost falls squarely between 60 percent and 70 percent.

It is interesting to note that in this example even though the costs for the submerged arc welding consumables are higher than those for the gas-shielded processes, the overall total cost for depositing one pound of weld metal is lower for submerged arc.

The message is that for the open arc processes, a 10 percent reduction in labor costs will be greater than a 10 percent reduction in consumable costs. Once again, using 3/32 in UltraCore 70C as an example, a 10 percent reduction in labor and overhead will result in a transfer of almost $0.60 per pound of deposited weld metal to the bottom line. On the other hand, a push for a 10 percent decrease in consumable cost will only save $0.25 per pound of deposited weld metal.

Ultimately, moving towards a higher deposition rate process will provide the biggest bang for the buck by reducing the amount of time spent welding. And as we know, time is money.

It should be reiterated that these calculated costs listed in the accompanying tables are based on a $50 per hour labor and overhead rate and market list price for the consumables. In the real welding world, very few customers pay list price, so in few cases will these be the actual dollar values of the welding costs in any given welding fabrication shop. However, the trends observed here will nevertheless hold true. Welding processes that increase deposition rate and increase productivity will reduce the largest component of welding costs – labor and overhead.

Subscribe to learn the latest in manufacturing.