Why Aren’t More Manufacturers Using Minimum Quantity Lubrication?

While the idea of sustainability is becoming better defined and understood, many manufacturers are still not taking the necessary steps to implement newer proven technologies that foster sustainability. Why?

Posted: March 20, 2012

Metalworking operations have an obligation to develop sustainable manufacturing solutions. Some might think this a bold statement. While the idea of sustainability is becoming better defined and understood, many manufacturers are still not taking the necessary steps to implement newer proven technologies that foster sustainability.

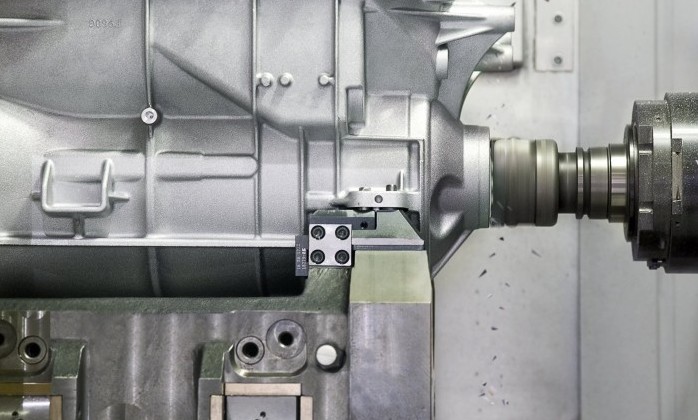

One of those technologies is Minimum Quantity Lubrication (MQL). MQL eliminates large quantities of water and oil-based coolants and replaces them with a small quantity of lubricant mixed with air. This air-oil stream is precisely metered and delivered to the cutting tool’s edge. The philosophy behind MQL is based on a simple principle – more is not always better. Use only what’s needed for the application, because enough is as good as a feast.

Manufacturers applying MQL are reaping many sustainable benefits. Their workers are safer, with both short and long-term benefits. Operators, skilled tradesmen, and engineers are no longer exposed to the toxicity, bacteria, and fungi risks that come with traditional “wet” machining. The small amount of oil used for MQL is generally based on vegetables or esters, which are less harmful to humans. Our environment is cleaner because there are no used cutting fluids requiring stringent disposal – this benefits everyone and helps change the “dirty” perception of manufacturing.

Oil and other wastes present significant disposal impacts and implications to our environment. While legislation and regulation specify mitigation to the environment, enforcement of this legislation is challenging, expensive, and difficult. Metal chips produced during MQL machining are nearly dry and much cleaner than conventional approaches. Near-dry chips are easier to recycle and more valuable as a recycled material.

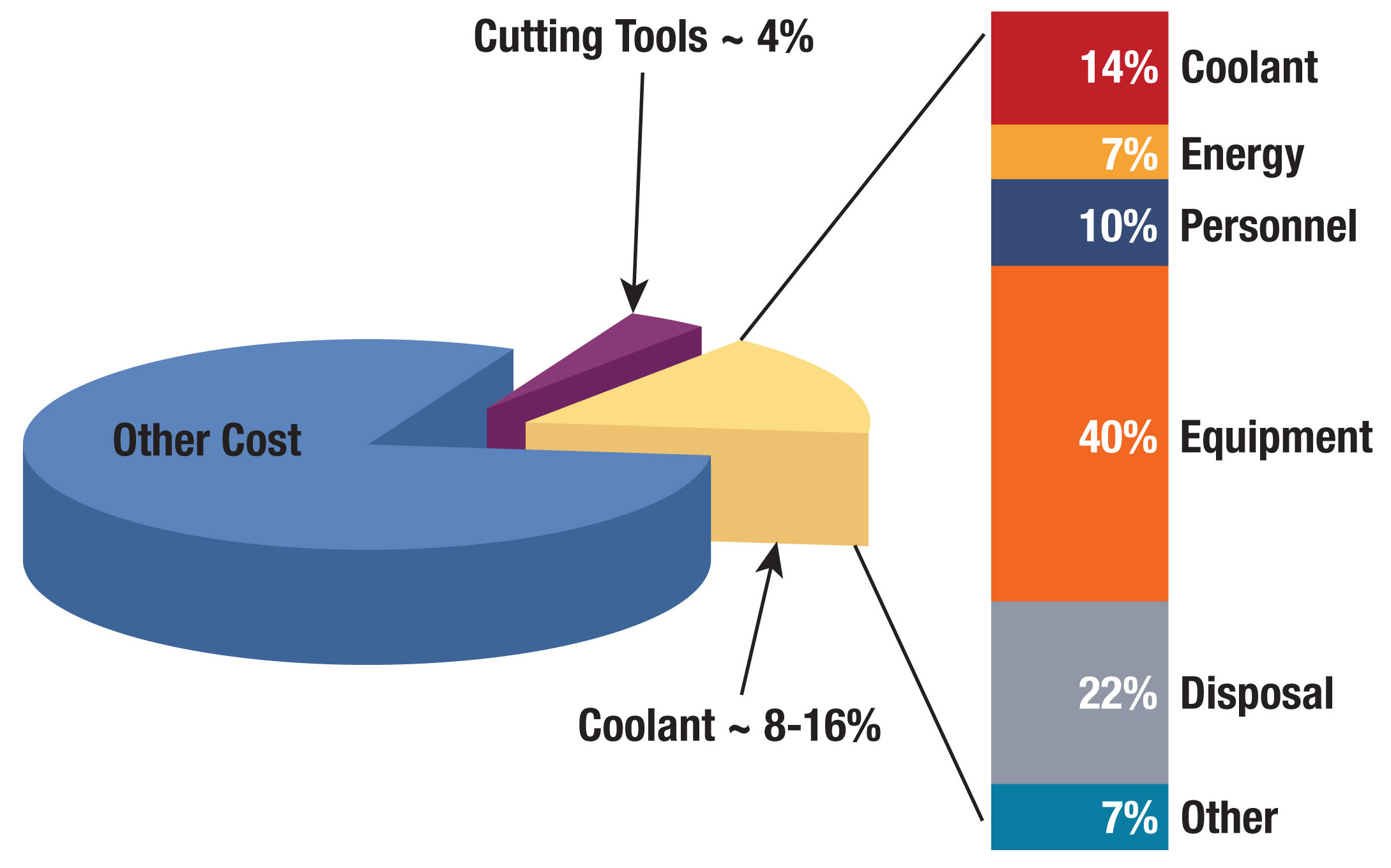

Most manufacturers still associate sustainability with higher costs. However, when we break down the investment and operating expenses of “wet” manufacturing systems, one begins to understand just how much these conventional systems cost. Transferring, recycling, and pressurizing coolant results in significant costs for coolant supply, filtration, and mist collection equipment. Operating “wet” equipment produces increased and on-going lifecycle costs in the form of energy consumption, chemical maintenance, water make-up, disposal of used cutting fluids, and then starting the cycle of waste/recovery all over again by replenishing consumed fluids.

The pie chart illustrates the investment and operating expenses of a typical machining system producing a large volume of aluminum transmission components for automobiles, with water soluble coolant.

So with all of these benefits, why aren’t more manufacturers implementing MQL technology? As an industry, why aren’t we behaving more responsibly to implement sustainable manufacturing processes and systems in our factories? In most cases, do we hide behind the myth that sustainability adds cost? In the case of MQL, we have proven sustainability pays for itself. So again, why aren’t more manufacturers insisting on MQL solutions? Is it fear of new technology or the cultural change associated with it?

These questions and others are a real challenge for our industry. Until we answer them and have the courage to change our behavior, we cannot embrace a new idea like sustainability. So, what is the worst thing that can happen? The answer is that we may miss the next real technology opportunity to restore American manufacturing leadership – and no one can afford that.