How to Clean Up Cast Iron Machining

This case study explains how Chemtool formulated a novel metalworking fluid with Dow Chemical to clean up the cast iron machining operations of a Midwest machine shop.

Posted: March 20, 2012

A novel metalworking fluid based on new oil-soluble polyalkylene glycol (OSP) base fluid technology from the Dow Chemical Company has solved a chronic residue build-up problem in the cast iron machining operations of a Midwestern U.S. manufacturer.

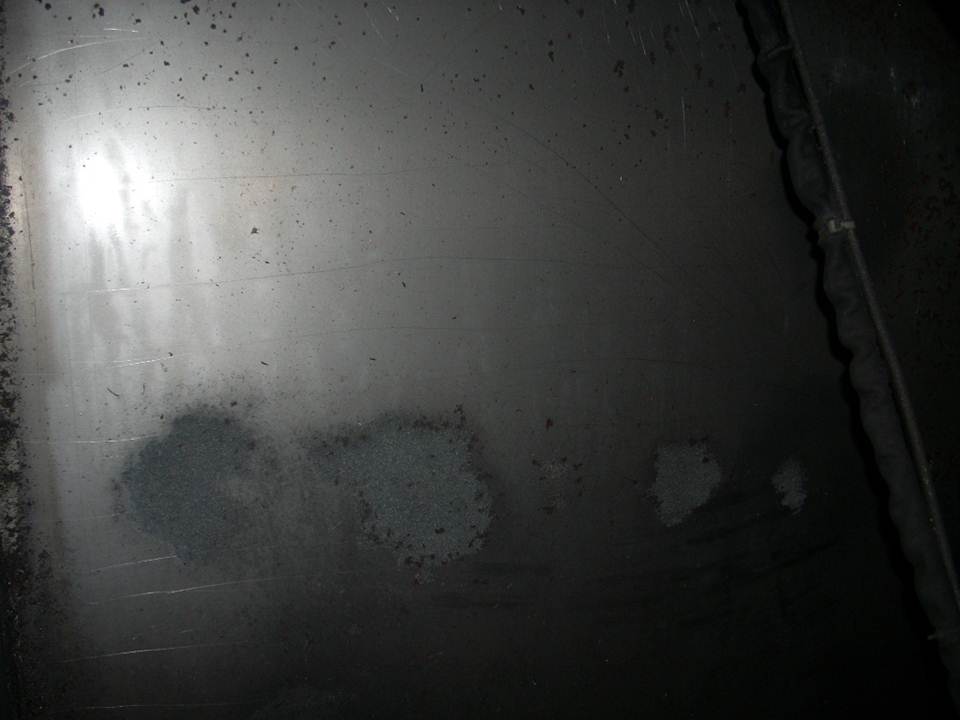

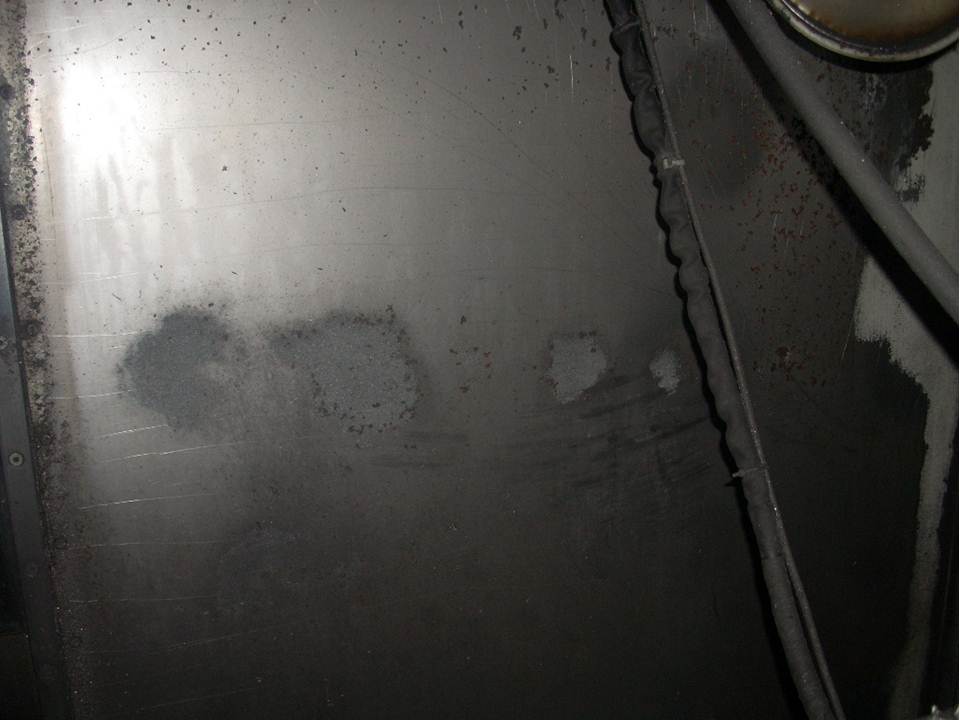

Formulated by Chemtool, Incorporated (Rockford, IL), the new fluid has virtually eliminated build-up of hard-to-remove cast iron residue that coated CNC mills, lathes and surrounding enclosures, obscured operator visibility and increased the potential for wear, which created maintenance and resulting downtime issues.

STICKY SITUATION

The manufacturer produces flow control actuators and gearboxes used by the petroleum and processing industries. The company’s production operations include machining ductile cast iron on CNC mills and lathes as well as drilling and tapping. A fully synthetic metalworking fluid initially used in the company’s mill and lathe cutting operations produced a sticky residue when combined with cast iron particles and graphite produced during machining.

This residue was broadcast to the machine bodies, chucks, seals, enclosure walls, way covers and enclosure windows where it accumulated in a thick coating that could only be removed by shutting down the machines for arduous manual cleaning.

The manufacturer’s water source and sump system contributed to the challenge. The water is relatively hard (25 grains), contains 21 ppm of chlorides, and some bacterial load. The fluid sumps are small, with the largest only 80 gal. Because the company’s machining operations run fast and hot, 24 hours per day, there is little time for fines to settle, causing build-up in the sumps and premature filter clogging. Water evaporation from the sumps causes hardness and chloride levels to increase, which can lead to fluid emulsion breaks and corrosion problems in the system.

ON THE CASE

The manufacturer called on Chemtool to help solve its residue problem because it is one of the world’s largest privately held manufacturers and custom formulators of lubricants and specialty cutting fluids, mold-release compounds and sealants for manufacturing and maintenance operations.

According to Rick Butler, the technical manager for fluids development, “Our initial suspicion was that the rust inhibitor in the prior metalworking fluid was interacting with the other formulation components and creating a high viscosity residue that was binding up fines. We’ve seen this before in cast iron machining operations where cutting produces fine iron particles as well as inter-granular graphite. This combination is very susceptible to agglomeration and cutting fluid chemistry can increase this tendency.”

As an initial step, Chemtool recommended a trial of a semi-synthetic polyalphaolefin (PAO) base fluid, which contained an extreme pressure additive with increased surfactant content to improve rinse results. Machining performance during the trial remained acceptable, but the formulation still left a greasy film on the machine and surrounding surfaces.

A subsequent trial was performed using a synthetic hydrocarbon fluid with an even higher level of detergency. Results improved— the residue produced by the system was less tenacious and could be removed by manual wipe down. Still, there was a need for a more effective solution that would eliminate the residue problem altogether.

OSP BASE FLUID PROVIDES THE ANSWER

ChemtooL turned to new oil-soluble polyalkylene glycol (PAG) base fluids from Dow. Polyalkylene glycols are polymers made from the reaction of starter molecules with alkylene oxide monomers, e.g. ethylene, propylene oxides. They typically offer favorable properties including high viscosity index values, low pour points, and excellent film forming properties.