CNC: It’s All About Networking

Competitive Edge: Machine control can now provide data to every department in the shop, multiple facility companies, even outside partners, to keep everyone “in the know.”

Posted: February 13, 2012

(click on photos to enlarge them)

(click on photos to enlarge them)

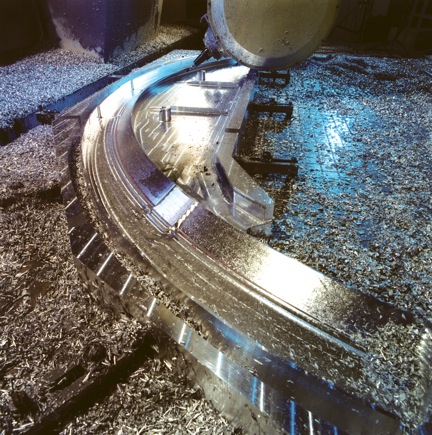

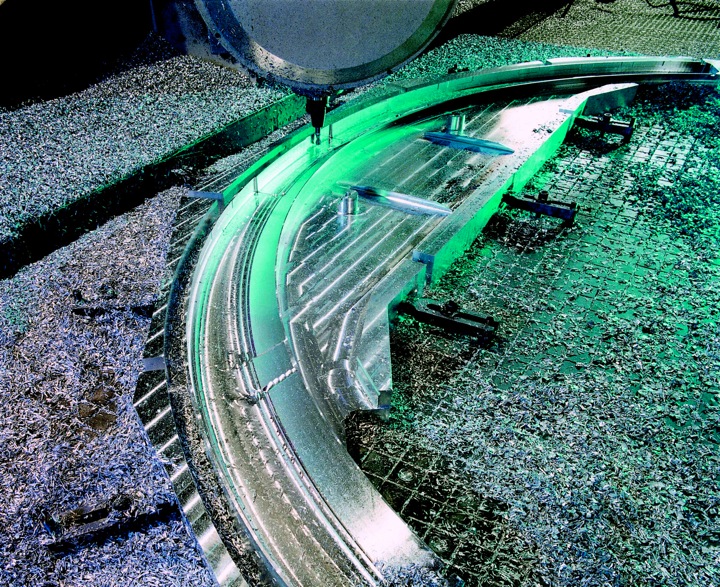

From the time a part is designed, either by your shop or your customer, to the materials purchase, the program translation for machining or fabricating and even the final production numbers, the CNC on your lathe, mill, waterjet, laser, stamping press or transfer line can contribute to the body of knowledge being used for evaluation.

This ability to integrate all machine and production data into a shop or company network is becoming more and more important as a way to grow increasingly competitive – and remain that way. By obtaining this level of information from chip to crating, as I like to say, your operation can become more productive and more rigorous in its product and process evaluation, plus spot all the weak points in your metalworking world.

I’ve just defined a buzzword you hear a lot today – PLM (product lifecycle management) – and I’m addressing at least a part of that concept here. Once thought to be something of value only for the big automotive, appliance, consumer electronic or other mass markets, this notion of information technology (IT) management is gaining traction at every level of the machine tool and metal fabrication worlds because it allows management, machine operators, programmers, maintenance personnel and machine builders alike to be connected (ok, networked) in an overall system, with the CNC as the hub.

Once again, if you grew up out in the country, you might remember the old party line. During the early days of rural phone service, everyone in a town had the ability to listen in. In many ways, today’s CNC simply facilitates a modern equivalent of this network by concentrating all the IT-related functions into a single process suite, using various modules. Best of all, it’s all standard on the more advanced CNC brands.

For example, imagine all function libraries needed to interface every machine control to a server being readily available in the control. The use of all NC, PLC and HMI functions across the entire company network could be utilized to generate and configure every function. Naturally, security is afforded on each machine with full encryption and safe storage.

Or, as another example, imagine the drive control and workflow data are all available from the virtual NC kernel (VNCK) and that all tool, production data and program management are available company-wide, again through the CNC communication portal. Or imagine all machine diagnostics are readily accessible to an operator, remote production data manager, maintenance personnel and even external machine builders or control manufacturers through a firewall-protected channel. Or imagine real-time condition-based monitoring for evaluation of all mechanical and mechatronic components onboard the machine, accessible through the CNC.

Here’s the good part: There is no need to imagine all these features in a perfect-world control, because they already exist.

As always, it comes down to what you can do with the information in real-world terms. Well, now imagine you can streamline your shop floor or in-house production department to meet more customer requirements, while maintaining the viability and optimum productivity on every machine, assisted by the CNC, to provide your shop manager, IT department or customer Quality Control personnel with improved output and lower overall manufacturing cost lines, in an ongoing manner.

By combining all these IT functions on a chipcutting or metal fab machine into a single process suite within the CNC, today’s control can give you a better way to organize and implement more innovative and common-sense solutions to your production process challenges. Your machines can be commissioned more efficiently, made and kept much more productive. Most importantly, through all of these cumulative benefits you enjoy a greater degree of flexibility and responsiveness in your shop operation that will keep you competitive.

Sounds like some real-world upsides to me.