Buehler Celebrates Anniversary with Price Reduction on Grinding Discs

The price reduction on thir ReVel abrasives is the first of several customer appreciation activities held in conjunction with their 75th Diamond Anniversary.

Posted: March 21, 2011

Buehler (Lake Bluff, IL) lowered the price of their ReVel diamond abrasive grinding/polishing discs by up to 45 percent, part of a new price structure that celebrates their 75th Diamond Anniversary. Total savings may vary, as each global region and associated distributors set pricing independently.

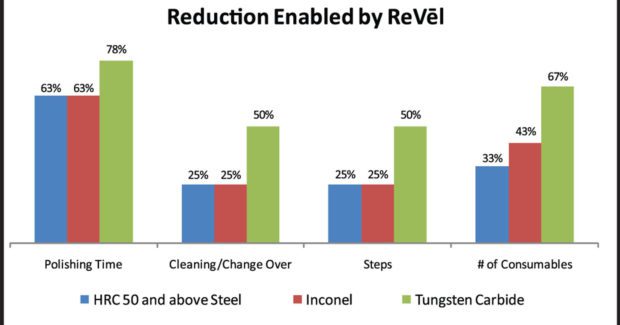

ReVel discs feature a diamond abrasive nanotechnology that creates a simultaneous material removal/polishing action. They prepare specimens from planar grind to final polish in four to seven minutes. These discs, at a minimum, reduce total polishing time by 63 percent, reduce cleaning/changeover time by 25 percent, reduce the number of steps by 25 percent and reduce the number of consumables to order by 33 percent.

The new lower pricing, which Buehler intends to maintain through 2011 and beyond, includes all disc types and sizes. ReVel A is used on ferrous materials with a Rockwell C Hardness of 50+ (481 Brinell), such as tool steels, ceramics and thermal spray coatings. ReVel B is used on nickel-based alloys such as Inconel®. They are available in 8 in (203 mm), 10 in (254 mm) and 12 in (305 mm) magnetic backed discs and come five per pack. Each ReVel disc has an optimal life of five uses (discs have a useful work life well beyond five uses, but grinding/polishing times may need to be extended to achieve equal results).

Buehler started in 1936 when Swiss immigrant Adolph I. Buehler saw the need for metallographic sample preparation equipment and optical inspection instruments for the American Midwest’s steel and automotive industries. His initial product line consisted of a mounting press, a polisher and optical inspection instruments. Originally founded in Chicago, Buehler moved to nearby Evanston in 1954 and then to their present 150,000 sq ft headquarter facility in Lake Bluff in 1981. The company has been an active exporter for much of its history and has more than 40 years experience operating in Asia and Europe.

Buehler abrasives are used throughout the world in manufacturing facilities, quality laboratories and universities to enable material characterization, ensure quality and perform materials research. The manufacturer will continue to announce special 75th Diamond Anniversary activity throughout 2011.