Wobble No More

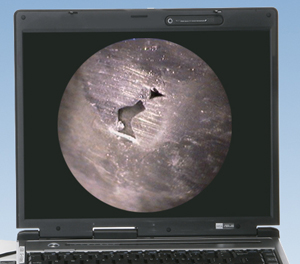

The Hawkeye Video Borescope Slide from Gradient Lens makes repetitive inspections faster and stable. Inspectors can quickly and easily mount parts and components and view borescopic images via a video system with three axis adjustments.

Posted: July 29, 2009

Conducting repetitive inspections with a borescope video system has been a somewhat wobbly endeavor – until now. With the new Hawkeye Video Borescope Slide from Gradient Lens Corporation (Rochester, NY), inspectors can quickly and easily mount parts and components and view borescopic images via a video system. Using the new video slide makes inspections faster and the resulting video images much more stable.

“We designed the video slide expressly for repetitive inspections and capturing borescope images,” says Dr. Douglas S. Kindred, GLC’s president. “Traditional, hand-held borescopic inspection lacks the stability necessary to capture clear still and video images, particularly at high magnification. The borescope video slide eliminates image instability and makes repetitive parts inspections much faster and easier.”

An overview of the Hawkeye Video Borescope series.

The Hawkeye Video Borescope Slide features:

- Three axis adjustments that offer flexibility and makes set-up easy.

- An adjustable stop that sets the inspection depth to easily locate a point of interest and prevents damage to the borescope tip.

- Locking mechanisms on all three axes that ensure repeatable results and allow users to slide either the borescope or the part being inspected.

- A standard, aluminum V-block that can handle mounting most parts. (Users can modify the V-block or replace it with a custom mount for oddly shaped parts.)

The video slide comes in lengths of 24 in (which works well with Hawkeye Precision Borescopes under 8 in long) and 48 in for use with longer scopes and larger parts.

Gradient Lens Corporation, 207 Tremont Street, Rochester, NY 14608, 585-235-2620, www.gradientlens.com.