How to Clamp Thin-Walled and Easily Deformed Parts

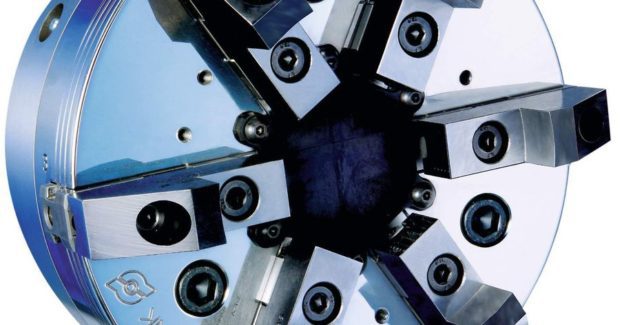

Using the ROTA NCR 6-jaw power chuck from SCHUNK, even pre-machined parts with diameters up to 1,200 mm can be perfectly centered on large lathes without deformation of the workpiece.

Posted: April 30, 2008

The clamping of thin-walled and easily deformed components is challenging. With its ROTA NCR 6-jaw power chuck, SCHUNK, Inc. (Morrisville, NC) offers a standard system for this type of workpiece. They have now standardized the sizes of the ROTA NCR with diameters of up to 1,200 mm and, in doing so, opened up the possibilities for precision workpiece clamping with large lathe chucks. The ROTA NCR consists of a central chuck piston, which has three inner pendulums positioned at 120 deg. Each pendulum is connected to two base jaws. The result is that the workpiece is centered between six contact points that can be adjusted in pairs. The clamping forces are aligned towards the chuck center. This means even pre-machined parts can be perfectly centered without deformation of the workpiece. This arrangement permits maximum roundness of workpieces with conventional jaw clamping.

The ROTA NCR is also available with centrifugal force compensation. A standard clamping cylinder is sufficient to actuate the lathe chuck. For certain applications, all six chuck jaws can be moved simultaneously and concentrically. Clamping is achieved simply by fastening the attachment screw in the piston. The jaw interface was selected to ensure compatibility with SCHUNK’s largest program of chuck jaws to save the user the purchase of costly and time-intensive special systems. The ROTA NCR is available in the sizes 165 mm, 200 mm, 250 mm, 315 mm, 400 mm, 500 mm, 630 mm, 800 mm, 1,000 mm and 1,200 mm. The large chucks can be employed on virtually all known lathes. In addition, extremely small chips, dust or huge quantities of coolant, as produced during the machining of gray cast iron, do not bother Schunk lathe chucks.

SCHUNK, Inc., 211 Kitty Hawk Drive, Morrisville, NC 27560, 800-772-4865, Fax: 919-572-2818, www.us.schunk.com.